Our Metal Shredders efficiently process light scrap metals like car shells, refrigerators, and metal drums. This powerful device shreds large materials into small pieces, optimizing size for easier transportation and recycling.

Send Inquiry Now

Recover valuable non-ferrous metals (aluminum, copper) from shredder material, municipal waste, e-scrap, and more using the Eddy Current Separator. Maximize resource recovery in recycling processes.

The Eddy Current Separator designed to separate valuable non-ferrous metals wherever non-ferrous metals have to be recovered or separated, e.g.where shredder material, municipal waste,WTE bottom ash, electronic scrap,wood chips, glass, batteries or foundry sand are processed.

The application scenarios include electronic waste recycling, scrap car dismantling, Cable recycling, aluminum-plastic separation ,construction waste treatment and other fields.

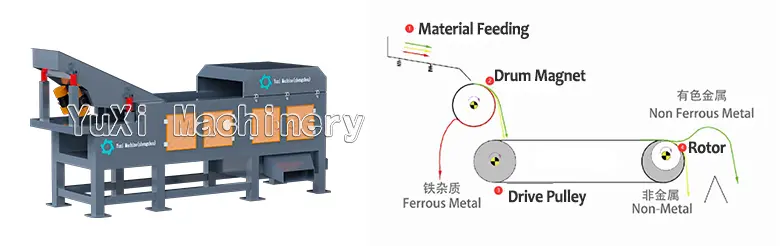

Material fed onto the conveyor belt of the eddy current separator,which moves it across the magnetic rotor where separation occurs.The magnetic rotor is surrounded by(but not attached to) a wear shell which supports the conveyor belt. This allows the rotor to spin independently and at a much higher speed than the wear shell and belt.

When a piece of nonferrous metal, such as aluminum, passes over the separator, the magnets inside the rotor rotate past the aluminum at high speed.

This forms eddy currents in the aluminum which in turn create a magnetic field around the piece of aluminum. The polarity of that magnetic field is the same as the rotating magnet, causing the aluminum to be repelled away from the magnet. This repulsion makes the trajectory of the aluminum greater than that of the non-metallic, allowing the two material streams to be separated.