Our Metal Shredders efficiently process light scrap metals like car shells, refrigerators, and metal drums. This powerful device shreds large materials into small pieces, optimizing size for easier transportation and recycling.

Send Inquiry Now

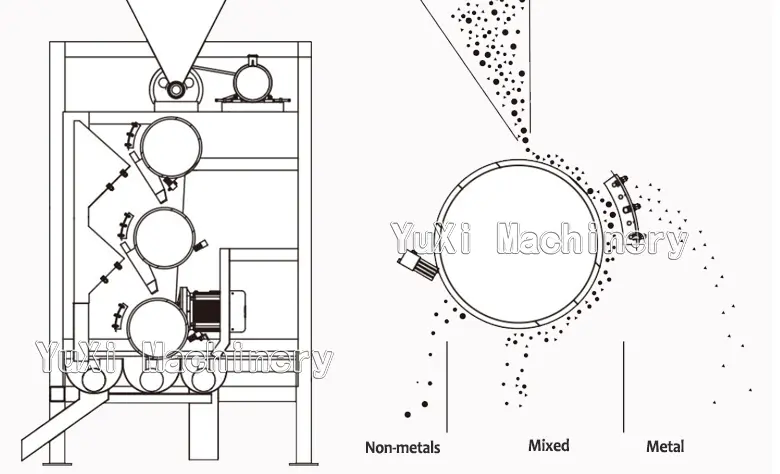

Achieve ultra-high purity metal and plastic separation with our High-Voltage Electrostatic Separator. This device uses an electric field to reach over 99.5% separation for resource recovery.

The high-voltage electrostatic separator is a separation device that uses an ultra-high-voltage electric field to charge and separate materials.The main separation materials are conductors (metals) and non-conductors (plastics).

The separation rate of electric separation can be adjusted according to the actual situation (such as material characteristics, the cost performance ratio of production capacity and separation purity, the uniformity of material particles, etc.), and theoretically it can reach more than 99.5%.

Electrostatic separator can separate metal and non metal particles,the separating efficiency can reach to 99%.

Using the difference in charging properties in the high-voltage electric field, the conductors are selected by electric suction and inertial force, and the non-conductors are adsorbed on the non-conductor by using the electric adsorption characteristics of the non-conductor. Rotate the top of the roller and use a brush to pick out on the other side.