Our Metal Shredders efficiently process light scrap metals like car shells, refrigerators, and metal drums. This powerful device shreds large materials into small pieces, optimizing size for easier transportation and recycling.

Send Inquiry Now

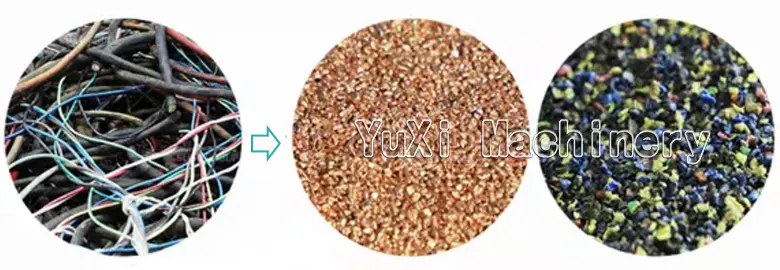

Process waste copper wires with our environmental Copper Wire Recycling Machine. Separate copper from plastic efficiently to achieve maximum resource recycling and recovery.

The copper wire recycling line is an environmental protection device used to process waste copper wires and separate copper from plastic, achieving resource recycling.

Various automobile circuit lines, motorcycle lines, battery lines, televisions, washing machines, refrigerators, air conditioners and other household appliances lines, communication lines, computer lines and other waste wires that are not suitable for processing by wire stripping machines.

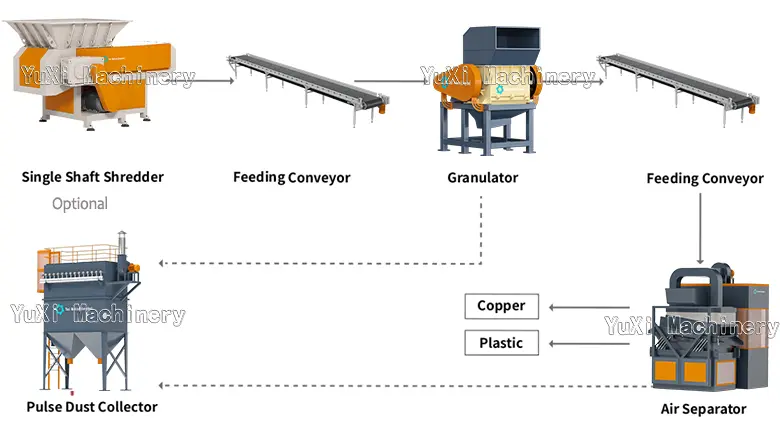

This cable wire recycling machine consists of a crusher, a fan conveyor, a vibrating screen, a dust collector, and electrical control.

After the waste wires and cables are shredded and crushed, they become plastic fragments and copper rice, which are made to move forward on the screen surface waveform. The core skin is separated by the dual effects of airflow suction and linear vibration of the screen box, and the copper rice, plastic, and the mixture of copper and plastic are sent out from different outlets.

The dust reaches the dust collector through the air duct.

The vibrating screen is controlled by frequency conversion, and the vibration frequency is adjusted according to different working conditions. The air volume is controlled by the regulating valve, and each action is controlled by buttons.