Our Metal Shredders efficiently process light scrap metals like car shells, refrigerators, and metal drums. This powerful device shreds large materials into small pieces, optimizing size for easier transportation and recycling.

Send Inquiry Now

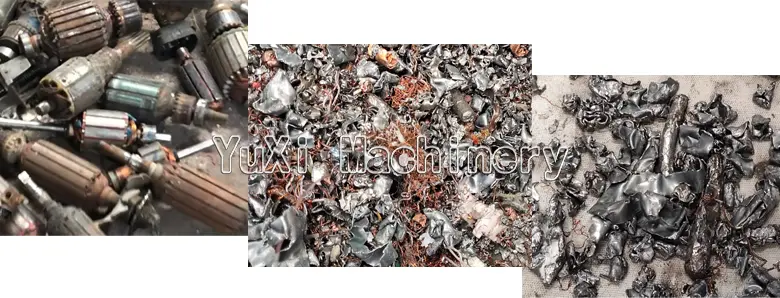

Process waste motor rotors with our recycling line. Utilizing disassembly, crushing, and separation, the system efficiently achieves resource recycling of metals from scrap motor components.

The waste motor rotor recycling production line is mainly used to process waste motor rotors. Through disassembly, crushing, separation and other processes, it realizes resource recycling.

Raw Material:All kinds of waste motor, rotors.

Final Product:Including the copper, aluminum, iron, plastic.