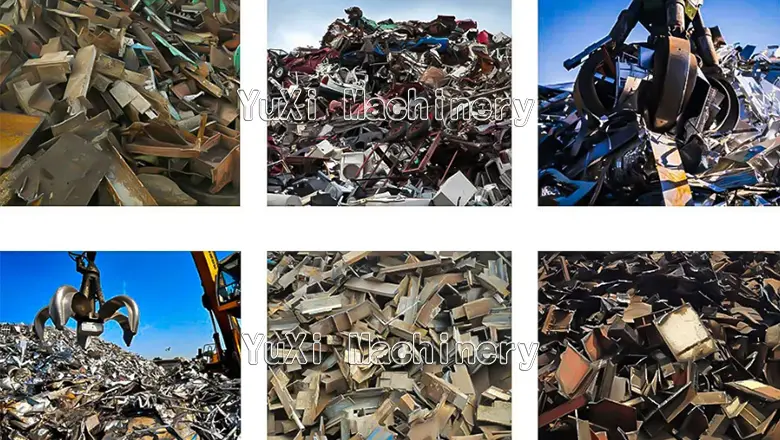

A Crocodile Shear is a hydraulic-driven tool used for the cold shearing of metal structures, section steel, and round steel. To get the best ROI, you need to look beyond the “shearing force” and focus on hydraulic efficiency and blade geometry.

1. Match Blade Length to Your Application

Engineering Experience: One of the most common mistakes is using a short blade for bulky scrap. If you are dismantling cars, a small 400mm blade will force your operator to make multiple inefficient cuts.

- The Rule of Thumb: * 400mmŌĆō600mm: Best for small profile scrap, pipes, and non-ferrous sorting.

- 700mm and above: This is the “sweet spot” for scrapped car dismantling. The longer blade allows you to bite through car pillars and body frames in a single stroke.

- Selection Tip: Yuxi offers lengths up to 1200mm. Always choose a blade slightly longer than the maximum width of your typical scrap.

2. Evaluate Shearing Force vs. Material Grade

Engineering Experience: Don’t just look at the tonnage; look at the “shear section” capacity. Shearing 20mm round steel is very different from shearing a 10mm thick I-beam.

- The Range: We offer 8 grades of shearing force, ranging from 63 tons to 400 tons.

- Pro Tip: If you frequently process thick section steel or heavy structural beams, don’t settle for a 100-ton machine. Running a machine at its maximum limit 100% of the time leads to premature seal failure. Aim for a machine where your average work uses about 70-80% of its rated capacity.

3. Hydraulic vs. Mechanical Transmission

Engineering Experience: Old-school mechanical shears are jerky and loud. Modern hydraulic transmission is a game-changer for safety and precision.

- Why Hydraulic? Hydraulic shears offer low inertia, low noise, and stable movement.

- The “Flexibility” Factor: Hydraulic systems allow you to stop or reverse the shear mid-stroke. This is critical if the operator realizes a piece of scrap is incorrectly positioned or contains a “non-shreddable” hardened core.

4. Power Source and Portability

Engineering Experience: In many recycling yards, you don’t have a stable power grid right where the scrap is piled. Moving the scrap to the machine is expensive.

- Diesel Option: Look for a machine that can use a diesel engine as the power source.

- No Foundation Required: A huge advantage of our design is that there is no need for foot screws (anchor bolts). This allows you to place the machine on any flat, reinforced concrete surface and even move it around the yard as your scrap piles shift.

5. Ease of Maintenance and Safety

Engineering Experience: Because these machines work in dirty, dusty environments, the hydraulic seals and blade gaps are your primary maintenance points.

- Convenient Adjustment: Choose a machine that allows for easy adjustment of the blade gap. A gap that is too wide will “fold” thin metal instead of cutting it, causing jams.

- Small Volume/Lightweight: A compact design doesn’t mean “weak”ŌĆöit means the hydraulic manifold is integrated efficiently, making it easier to clean and service.

EngineerŌĆÖs Procurement Checklist:

- Blade Length: Is it 700mm+ for car dismantling or 400-600mm for sorting?

- Tonnage: Does the shearing force (63t to 400t) match your thickest material?

- Power: Do I need a diesel engine for site mobility?

- Operation: Is it hydraulic-driven for low noise and stable movement?

Summary

Product: Crocodile Shears Machine (Alligator Shear) Applications: Metal recycling, scrap car dismantling, smelting and foundry cold cutting. Key Technical Terms: Hydraulic transmission, cold shearing, 63-400 tons shearing force, diesel power option.

Request Quote

Request Quote