In a scrap yard or smelting plant, a baler is more than just a compressor; it is a strategic tool to slash logistics costs. A poor choice results in bales that donŌĆÖt meet steel mill density standards and frequent hydraulic leaks that paralyze production.

1. Look Beyond “Nominal Pressure”ŌĆöCheck System Stability

Engineering Experience: Many manufacturers claim high pressure, but if the hydraulic station design is poor, the oil temperature will spike within two hours, causing efficiency to plummet.

- Integrated Hydraulic Control: Prioritize machines using integrated hydraulic valve blocks. This design significantly reduces hose connections. My experience: fewer joints mean a 60% reduction in leak risks and much more stable system pressure.

- Cooling Systems: If you operate in hot climates or require 24/7 continuous cycles, always check for a high-efficiency forced cooling system (air or water-cooled).

2. Frame “Rigidity” Determines Lifespan

Engineering Experience: A baler box faces massive outward expansion forces when squeezing scrap steel. IŌĆÖve seen many low-quality frames warp after six months, preventing the lid from sealing properly.

- Wear-Resistant Liners: Check if the compression chamber is fitted with high-strength liners (such as Manganese steel). Liners are consumables; if they are high-quality and easy to replace, they will protect the main frame for decades.

- Anti-Rust & Corrosion Protection: Scrap metal often carries cutting fluids or acidic rainwater. Choosing a frame treated with sandblasting and high-grade anti-rust coating prevents structural weakening caused by chemical corrosion.

3. Choose the “Discharge Mode” Based on Material

Engineering Experience: Selecting the right discharge method based on your material type can save massive amounts of labor.

- Side-Push / Turn-Out: Best for light, thin materials; offers the fastest cycle speed.

- Forward-Out (Front Push): Best for heavy scrap steel or large aluminum blocks. The push is more direct, resulting in tighter, denser bales.

- Manual Removal: Only suitable for very small hobbyist machines; avoid this for industrial-scale lines.

4. Component Universality and Serviceability

Engineering Experience: Many international buyers overlook the difficulty of sourcing spare parts.

- Brand-Name Components: Ensure pumps, valves, and seals are from reputable brands. In an emergency, being able to buy a standard seal ring from a local market is far more important than waiting ten days for an international shipment.

- Piston Rod Protection: Check for dust boots or shields on the piston rods. Scrap metal debris can easily score a rod, leading to seal failure and pressure loss.

5. Bale Standardization and High Density

Engineering Experience: Steel mill electric furnaces have strict requirements for “charge” size.

- Logistics Fit: Ensure the resulting bale dimensions maximize the payload of your shipping containers or trucks.

- High Density: A superior baler compresses aluminum or steel until it is as solid as a rock. This eliminates “empty space” shipping fees and increases the recovery rate (reducing burn-off) during smelting.

EngineerŌĆÖs Procurement Checklist:

- Valve Integration: Are hose connections minimized?

- Chamber Construction: Are there replaceable manganese steel liners?

- Oil Temperature Control: Is there an automatic cooling system?

- Logic Control: Is it equipped with a PLC for one-touch automated baling?

Summary

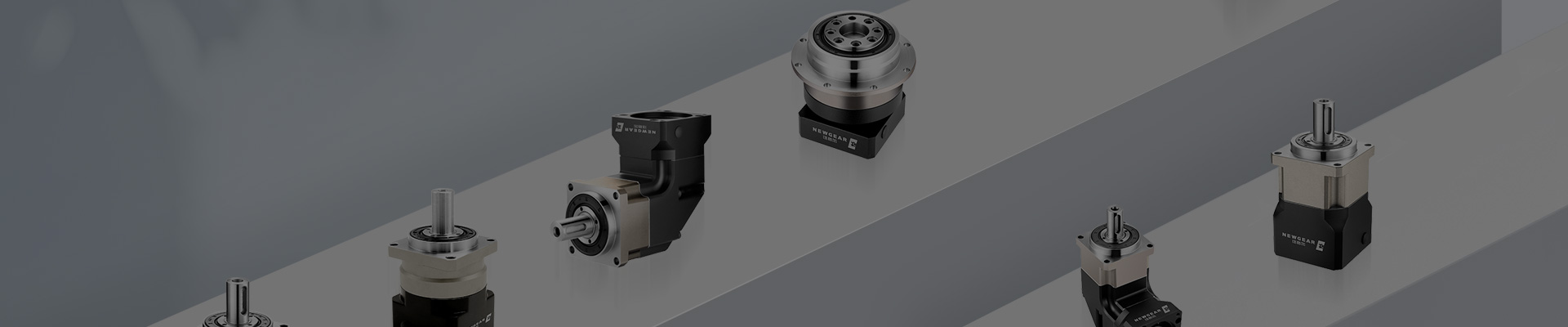

Product: Metal Baling Machine (Metal Hydraulic Baler) Applications: Scrap steel yards, aluminum processing, smelting plants. Key Technical Terms: Integrated hydraulic control, anti-rust design, high-density baling, reduced logistics costs.

Request Quote

Request Quote