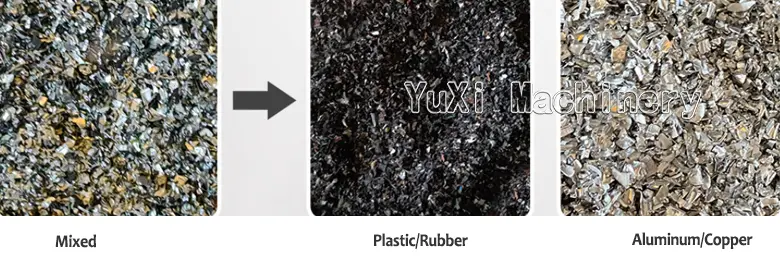

In the recovery of copper-plastic mixtures, circuit boards, and aluminum-plastic composites, the Electrostatic Separator is the final gatekeeper. Choosing the right unit is about more than just the voltage; itŌĆÖs about control, climate, and purity.

1. Look for “Composite Electric Field” Technology

Engineering Experience: Traditional single-corona separators often struggle with very fine powders.

- The Tech: Ensure the machine utilizes both a high-voltage corona electric field and a static electric field. This combination ensures that even the smallest conductive particles (metals) are effectively “kicked” away by inertial force, while non-conductors (plastics) remain pinned to the roller by adsorption.

- Why it matters: Without a composite field, your recovery rate will hover around 90-92%. To hit that 99.5% goal, you need the dual-action force.

2. The Criticality of Material Dryness

Engineering Experience: Humidity is the #1 enemy of electrostatic separation. If your material is damp, the physics of the charge transfer breaks down, and metals will “stick” to plastics.

- Intelligent Drying Mechanism: Choose a separator equipped with an intelligent drying system. This ensures the material maintains a consistent moisture level before entering the high-voltage field.

- Pro Tip: If your supplier doesn’t offer integrated drying or climate control within the sorting box, you will likely face significant downtime on humid days.

3. Voltage Stability and Automatic Regulation

Engineering Experience: Power grids in industrial areas can fluctuate. In an electrostatic field, a drop of even a few kilovolts can drastically change your sorting trajectory.

- Automatic Voltage Regulation: Ensure the machine has an automatic voltage regulation device. This keeps the ultra-high-voltage field stable regardless of external grid fluctuations.

- Safety & Stability: The power supply should be capable of maintaining a stable charge for hours of continuous operation without arcing or overheating.

4. Dust Control and Negative Pressure

Engineering Experience: Fine dust from circuit boards or minerals is not only a health hazard but can also cause “short circuits” in the electrostatic field.

- Closed Sorting Box: Look for a fully enclosed design.

- Negative Pressure System: A high-quality separator must be integrated with a negative pressure dust removal system. This keeps the internal environment clean, ensuring the electric field remains focused on the material, not the dust in the air.

5. Maintenance: Brushes and Rollers

Engineering Experience: The roller is the heart of the machine, and the brush is its cleaner. If the brush fails, the non-conductive plastic builds up on the roller, ruining the separation.

- Structural Access: Choose a machine with a modular design that allows for quick inspection of the roller surface and easy replacement of the cleaning brushes.

- Low Noise: From a workplace safety perspective, look for equipment with an operating noise of Ōēż75dB.

EngineerŌĆÖs Procurement Checklist:

- Separation Purity: Can the machine reach 99.5% for your specific material (e.g., waste circuit boards)?

- Climate Control: Does it have an intelligent drying mechanism?

- Dust Management: Is there an integrated negative pressure dust collector?

- Voltage Control: Does it feature automatic regulation for field stability?

Summary

Product: High-Voltage Electrostatic Separator (Electrostatic Sorting Machine) Applications: Copper-plastic separation, Aluminum-plastic recycling, E-waste circuit boards, mineral sorting. Key Technical Terms: Corona electric field, conductor/non-conductor separation, 99.5% purity, negative pressure dust removal.

Request Quote

Request Quote