Our Metal Shredders efficiently process light scrap metals like car shells, refrigerators, and metal drums. This powerful device shreds large materials into small pieces, optimizing size for easier transportation and recycling.

Send Inquiry Now

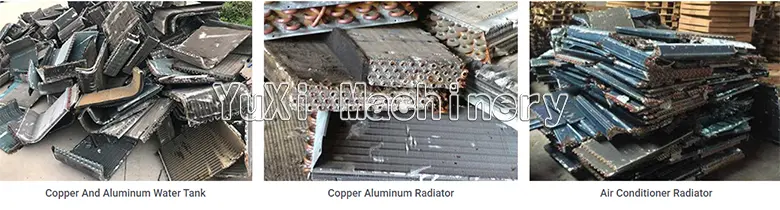

Maximize metal recovery from waste radiators (AC & car) using our highly automated recycling line. It utilizes crushing and sorting to efficiently recover valuable copper, aluminum, and iron, minimizing labor costs.

The waste radiator recycling production line is mainly used to process used radiators (such as air conditioners and car radiators), and through processes like crushing and sorting, it realizes the recycling of metals such as copper, aluminum and iron.

The entire recycling production line has a high degree of automation, reducing labor and maximizing the recycling of high-value materials.

Waste Radiator Recycling Equipment handles large radiators and ≤15cm motor rotors. It crushes materials into 3cm pieces, separates iron with a magnet, and sorts copper, aluminum, and plastic by airflow.

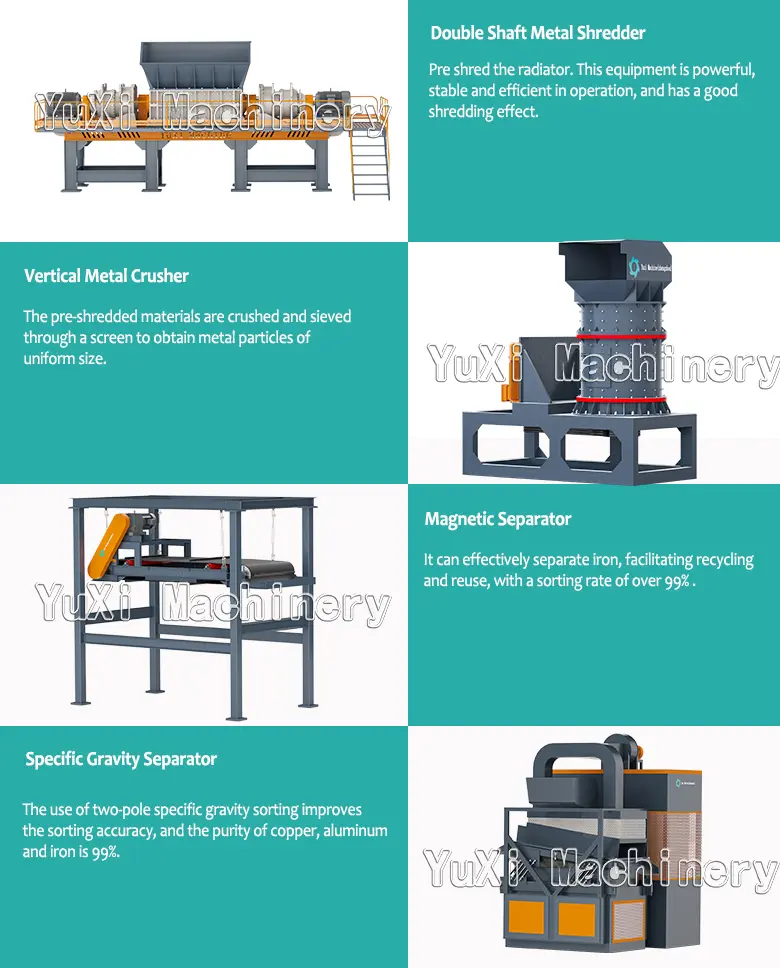

Double shaft shredder

Pre shred the radiator. This equipment is powerful, stable and efficient in operation, and has a good shredding effect.

Vertical crusher

The pre-shredded materials are crushed and sieved through a screen to obtain metal particles of uniform size.

Magnetic separator

It can effectively separate iron, facilitating recycling and reuse, with a sorting rate of over 99%.

Specific gravity separator

The use of two-pole specific gravity sorting improves the sorting accuracy, and the purity of copper, aluminum and iron is 99%.

Dust removal

The generated dust is collected centrally through pipelines, featuring strong dust cleaning capacity and high dust removal efficiency.