Our Metal Shredders efficiently process light scrap metals like car shells, refrigerators, and metal drums. This powerful device shreds large materials into small pieces, optimizing size for easier transportation and recycling.

Send Inquiry Now

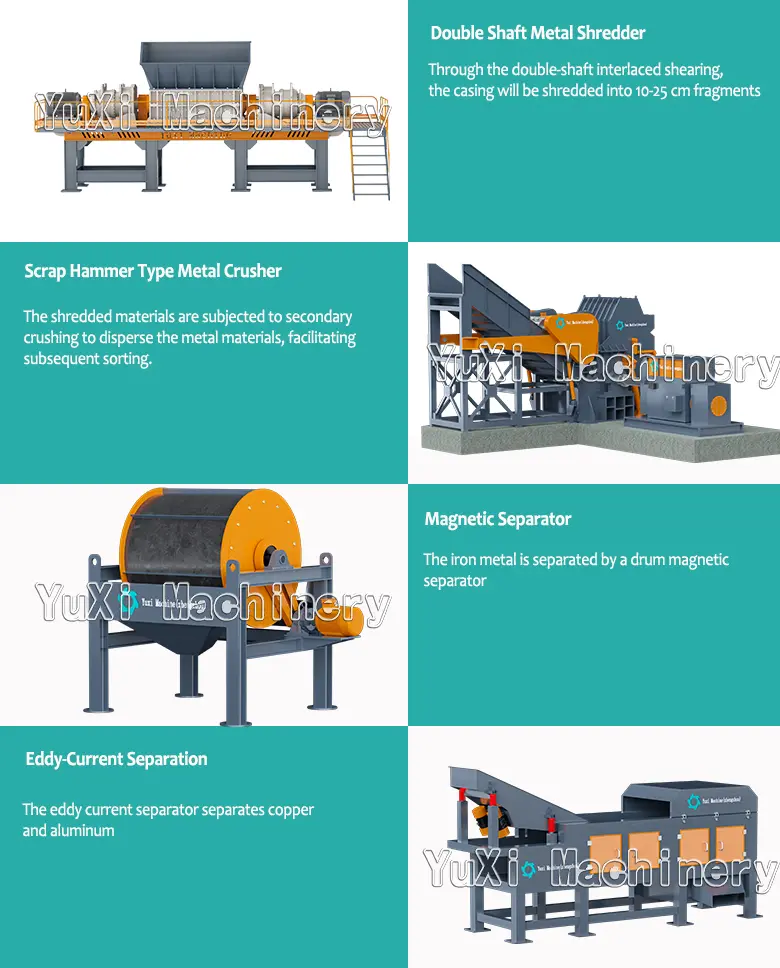

Efficiently recycle waste refrigerators with our dedicated production line featuring shredders, crushers, and eddy current separators. Recover high-value materials including iron, copper, aluminum, and plastic.

The waste refrigerator recycling production line includes a double-shaft shredder, metal crusher, eddy current separator, dust removal equipment, etc., which can effectively separate and recycle materials such as iron, copper, aluminum and plastic in waste refrigerators.

The waste refrigerator recycling line is also capable of recycling other household appliances such as TV sets, washing machines, and air conditioners.